Door fillings. Sandwich panels and their purpose.

Door fillings (our sandwich panels) are available in various versions and thicknesses, and their structure varies depending on their purpose. The multitude of fillings, linings and inserts (ALU, dB33, dB 38) means that they can be adapted to the specific requirements of even the most demanding customer. Contractors in Europe appreciate our boards for their versatile application possibilities, outstanding material properties and the possibility of easy, quick and practical processing. A very wide range of products enables the selection of a product according to various types of construction styles and investors’ tastes.

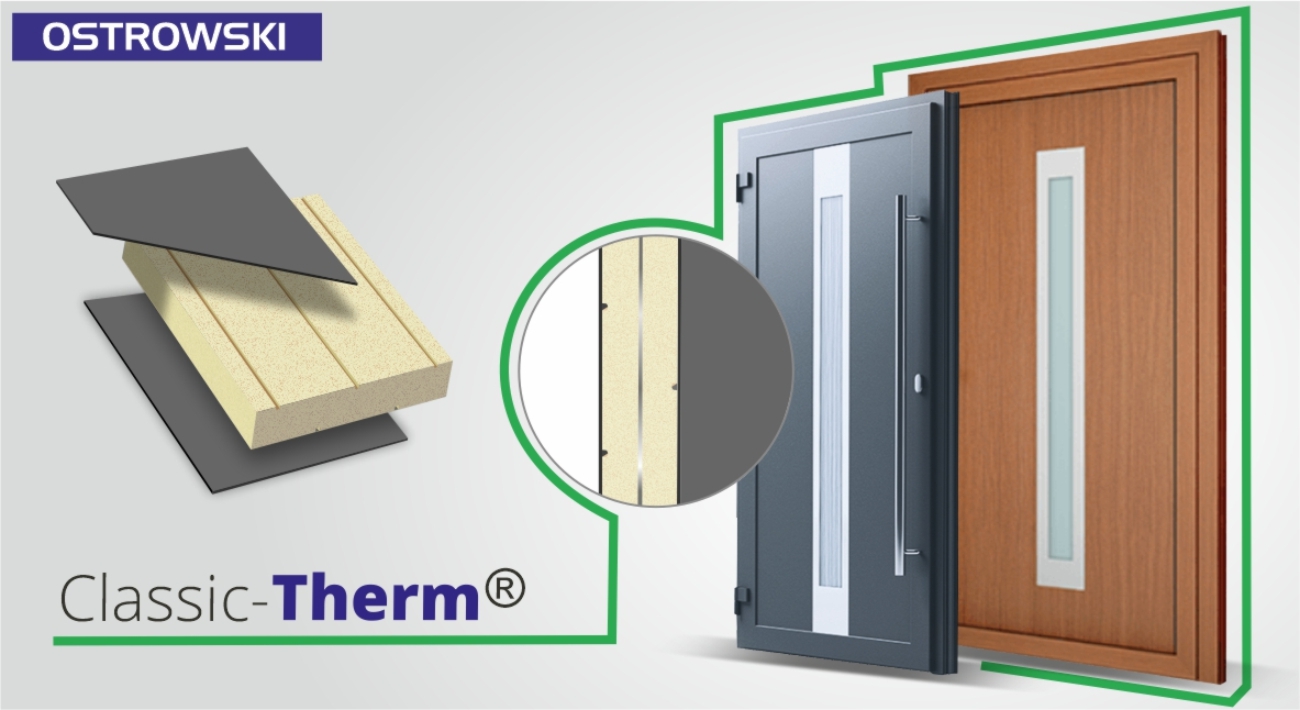

Door fillings and their structure

The door filling is a panel made of boards with various types of facings and fillings. The materials used in the production of the sandwich panel are selected depending on the future use of the product. In our product offer, there are, among others: PVC panels, HPL laminate panels, aluminum door panels, soundproofing panels, anti-burglary panels, panels finished with sheet metal or sandwich panels finished with plywood. The door panel determines the unique character, appearance and properties of the entrance door. The door filling is a decorative element embedded or installed in the door leaf that influences the visual effect. Door fillings. Sandwich panels and their purpose. Door panels are not only supposed to look good and give the building a unique character, but also increase the functionality of the door.

Types of door fillings

Overlay filling – these are high-quality panels that cover the entire door leaf frame, both on the inside and outside. As a result, smooth, elegant surfaces are created on both sides. The door frame itself remains visible, and the door leaf is consistent and aesthetic.

Batch filling – it is a filling inserted directly into the door frame. The leaf profile visibly surrounds the filling from the outside and inside. This solution has the advantage that after years of use, by replacing the filling, you can refresh the appearance of the house according to the current preferences of the residents. The structure of the batch doors – it is very similar to the window structure, with the difference that the glass is replaced by a door panel called a door filling (sandwich panel). External doors consist of a door frame, door leaf frame, handle, hinges and door filling.

Sandwich panels for door fillings and the external surface

Our offer includes door fillings such as: Classic-Therm PVC, Classic-Therm HPL, Classic-Therm ALU, Classic-Therm SK – differing in the outer layer of the panel. The type of outer layer directly affects the appearance of the final product, but also its price and properties. HPL door panels are covered with laminate. There are different types of laminates from different manufacturers. They have different textures, colors, thicknesses, and thus are more or less durable. Those imitating wood and having a three-dimensional structure are hard to distinguish from veneers at first glance.

Sandwich panels and their inner layer (core)

The door panels can be made according to the customer’s requirements. XPS door fillings are the most common. XPS core made of extruded polystyrene with a closed-cell structure is an excellent insulation material, resistant to moisture and frost. This core is characterized by high stiffness and compressive strength, which is why it is perfect for the joinery industry. The door core made of PUR foam is also very popular. The closed-cell structure of the PUR core allows for maintaining thermal, fire and mechanical stability in all environmental conditions for years of operation. PUR foam is resistant to weather conditions (rain, snow, wind) and its next advantage is the anti-moisture effect. The core has very good thermal properties and is resistant to mold and other fungi throughout its service life.

Woodwork is one of the most dynamic industries in construction, following the latest trends and technologies. Passive joinery has gained exceptional popularity in recent years. Ostrowski Sp. z o.o. as part of the woodwork, it has a huge selection of sandwich panels intended for door fillings, window extensions or the highest quality sill plates.

We invite you to our FB profile: Ostrowski – Producer of Sandwich Panels

We also offer the production of sandwich panels made to special customer orders. If you have any questions about our product range, please contact us directly:

Sales representatives:

Kamil Nierychło ![]()

![]()

Sales Europe

email: k.nierychlo@ostrowski.eu

tel.: +48 508 312 910