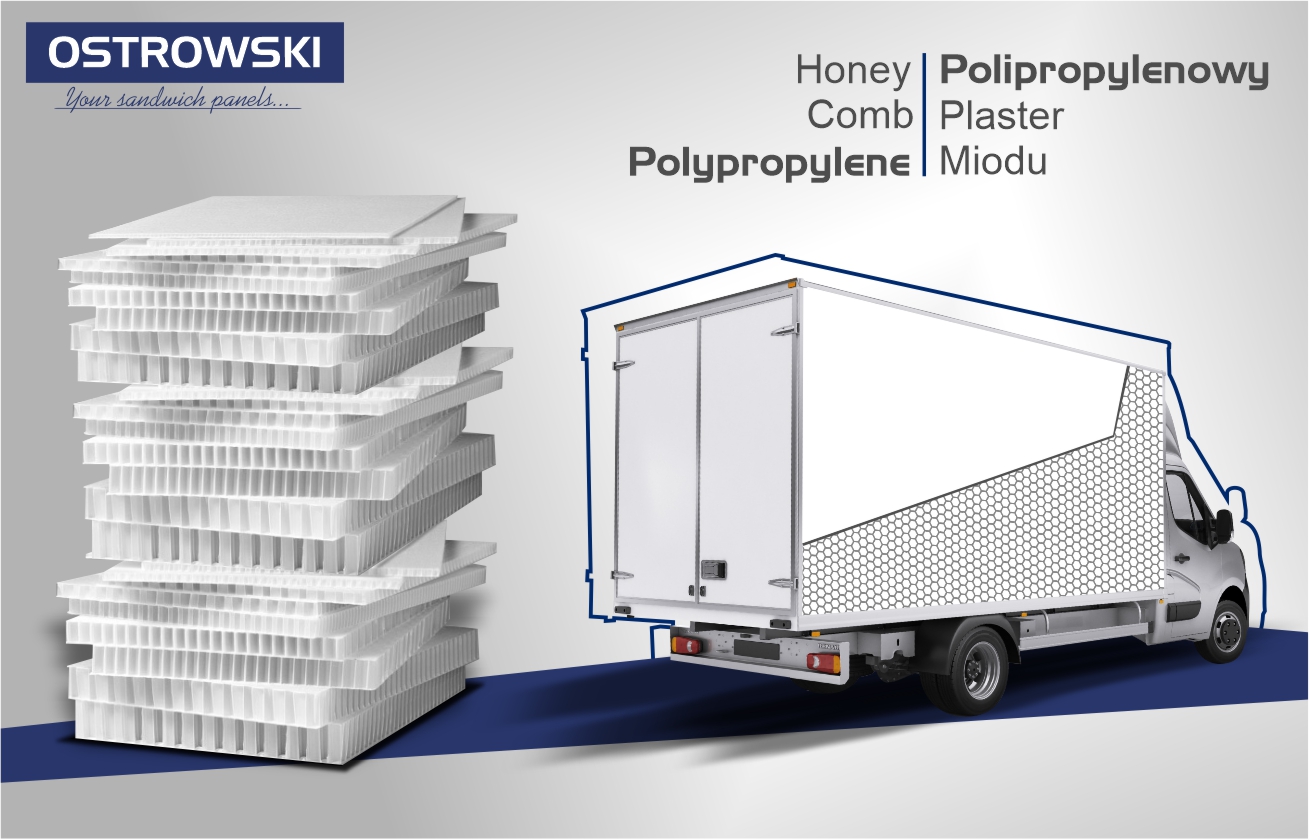

Polypropylene Honeycomb Sandwich panels. Composite polypropylene panels – application

Polypropylene Honeycomb Sandwich Panels. Honeycomb polypropylene is a type of cellular polypropylene, from which plates are produced in the extrusion process, they are mainly used for the production of superstructures for trucks, vans, container structures, structural and furniture elements, yachts or swimming pools. However, there are many more applications and their number is growing every year due to the development of new technologies based on composites. The basic raw material for the production of honeycombs is polypropylene. Thermoplastic, recyclable material from the polyolefin group. The polypropylene honeycomb structure is ideal for a semi-finished product, which is mainly used for the production of multi-layer components.

Sandwich panels made of polypropylene – automotive superstructures

The honeycomb structure of polypropylene is an ideal component for lightweight car bodies. The cell size, material density and thickness of the honeycomb core may vary according to your requirement. The integration of honeycomb production with the existing sandwich panel production process leads to further cost reduction and product quality improvement. Transport engineers all over the world are working on projects aimed at making vehicles (such as courier superstructures, isotherms, containers, vans, etc.) lighter, while maintaining their high strength.

Polypropylene and the automotive industry

Classic-Therm® GFK HC panels with a honeycomb core have exactly the desired combination of high-performance mechanical properties – they are light, very stiff and at the same time are an economically justified choice. In cost-sensitive automotive applications, customers highly appreciate the resource-saving technology and achieve very high levels of weight reduction with products such as sandwich panels with a polypropylene honeycomb core.

Honeycomb structure – honey comb

As for honey comb sandwich panels, polypropylene (PP) is currently the most popular, but PET (polyethylene terephthalate), biological plastics, PVC (polyvinyl chloride), ABS (acrylonitrile-butadiene-styrene copolymer), PS (polystyrene), PC (polycarbonate), PMMA (polymethyl methacrylate), PA (polyamide), PPS (polyphenylsulfide) and other materials are also suitable for use in this technology.

Honeycomb – core – interesting story

The first description of honeycomb cores in a sandwich structure for aerospace use can be found in Hugo Junkers’ patent of 1915. The Junkers patent shows sandwich structures of an aircraft with a rectangular honeycomb. Interestingly, one of the options for stiffening the steel shells of Junkers looks similar to the stiffening of the steel rings of the famous Elon Musk SpaceX ship.

Sandwich panels for cars supetructures / trailers superstructures – offer

Currently, our offer includes plates intended for: for superstructures, bodywork of vans, bodywork of trailers or, for example, as sanitary facilities. They include Classic-Therm® GFK standard HC, Classic-Therm® GFK powerlight HC with reinforced laminate, Classic-Therm® GFK highgloss HC with high gloss laminate or Classic-Therm® GFK stucco HC with high-impact laminate with bubble structure. Our offer, as a producer of sandwich panels, includes products characterized not only by high-quality workmanship, but also durability and functionality. We also offer the production of sandwich panels made to special customer orders. If you have any questions, please contact us directly – CONTACT

We also invite you to our FB profile: Ostrowski – Producer of Sandwich Panels